The modern manufacturing industry is in transformation. Just as more efficient, mechanized innovation during the Industrial Revolution increased productivity by leaps and bounds, new technologies such as AI, machine learning, iOT, and integration are transforming manufacturing processes today.

China represents about 35% of global manufacturing output and has invested heavily in technology to improve manufacturing efficiency. If other nations don’t adopt the same efficiency-enhancing technologies, they could lose even more ground to the world’s manufacturing superpower. Two years of pandemic supply chain woes: empty shelves, unfulfilled online orders, by turns empty, and clogged ports – have made it abundantly clear that change is needed.

The impact of failing to digitally transform

Apart from the outward negative impact to customers from technological stagnation, firms that can’t keep up with the pace of digital transformation face internal challenges as well. They tend to have inflexible legacy systems that do not speak to one another.

When infrastructure lacks flexibility, scattered data across multiple sources prevents access to comprehensive reporting and a single, reliable source of truth. Disparate systems and unreliable information also increase security and governance risk. When operating costs increase from the inefficiencies, revenue decreases precipitously. Manufacturing firms must leverage the right technology strategy with easy-to-use tools to combat these challenges.

Enter MuleSoft. MuleSoft helps integrate key systems, data, and applications. An API-led approach allows IT teams to reduce data silos and reuse key components, leading to the supply chain resilience that customers are hungry for.

Realize immediate benefits with current solutions

MuleSoft Accelerator for SAP offers pre-built APIs, implementation templates, reference architecture, and setup guides to accelerate manufacturers’ digital transformation. The Accelerator offers key solutions for manufacturers:

- Procure-to-pay allows you to manage vendor expenses and invoicing using Coupa.

- Quote-to-cash: Salesforce and SAP S/4HANA automates the opportunity-to-close process by synchronizing order, inventory, pricing, and customer data between Salesforce and SAP S/4 HANA.

- Quote-to-cash: B2B/EDI enables you to send and receive common EDI messages through Anypoint Partner Manager, including purchase orders. The solution also records important details in the EDI messages in SAP S/4 HANA. Orders that meet certain criteria are sent to Slack for follow-up or resolution by operations teams.

- Real-time and bulk data lakes integration empowers you to send customer, order, and inventory data from SAP S/4 HANA and Salesforce to the largest two data lakes in the market: Amazon S3 and Microsoft Azure for sales forecasting reporting and analytics in the BI tool of your choice.

We are also thrilled to announce a new Accelerator, MuleSoft Accelerator for Manufacturing. This Accelerator provides key pre-built integrations to Salesforce Manufacturing Cloud and Salesforce Rebate Management, enabling customers to better manage sales agreements, account forecasts, and rebates.

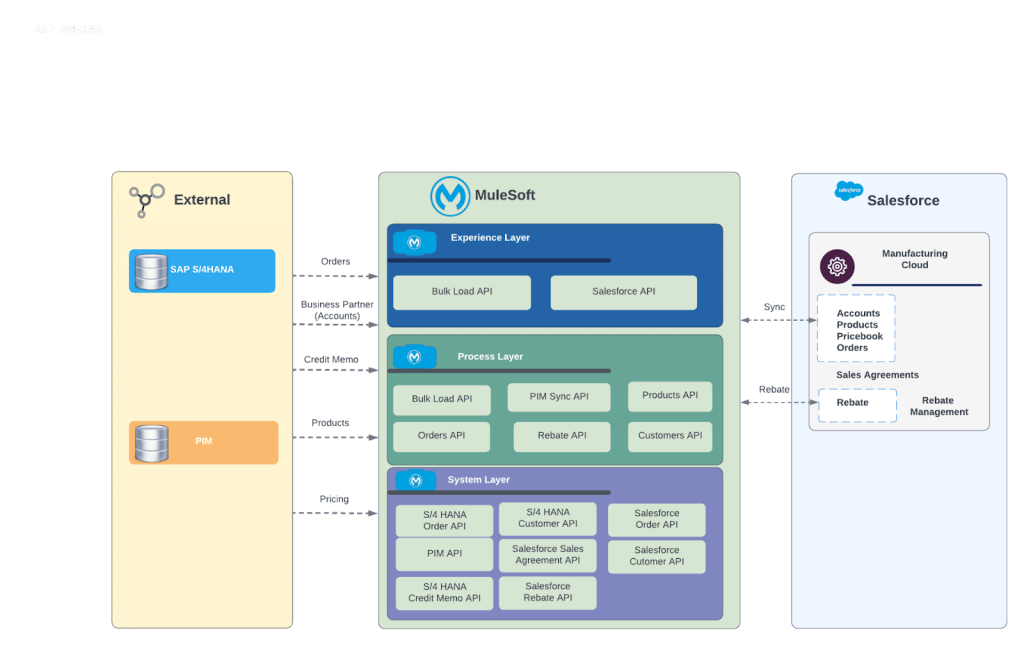

- Run-rate business management creates a unified view of sales agreements and account forecasts within Salesforce Manufacturing Cloud by pulling in customers, orders, and products from SAP S/4 HANA and PIM systems.

- Sales rebate management supports error-free automated financial processing of sales rebate payouts by syncing customer, rebate payout, and order data between Salesforce Manufacturing Cloud, Salesforce Rebate Management, and SAP S/4 HANA.

The diagram below depicts the scope of the current use cases broken down into system, process, and experience layers, key objects, and relevant systems.

Maintain equipment with an upcoming total productive maintenance solution leveraging MuleSoft, Tableau, and Service Cloud

Total productive maintenance, our next solution launching September 6, 2022 will enable manufacturers to send equipment data from OSIsoft PI, a prominent data historian, to Amazon Redshift for subsequent reporting in Tableau. Any spikes or deviations in the equipment data from the norm will be sent to Service Cloud via MuleSoft for investigation and remediation as customized. All endpoints are exchangeable and customers can use any combination of system, process, or experience APIs depending upon the business need.

Digital transformation in the manufacturing industry is a daunting task, but MuleSoft Accelerators for SAP and Manufacturing (available in Exchange) can accelerate time to value for manufacturers, intermediaries, and end-customers.

Learn more about the state of digital transformation through a manufacturing lens in our recent report.