Imagine a manufacturing world where every demand is accurately forecasted and every system seamlessly integrated. Seamless integration and accurate demand forecasting are critical for success.

Salesforce Manufacturing Cloud addresses the needs of a run-rate business by providing dedicated tools like Sales Agreements and Account Forecasts to manage long-term, ongoing relationships with customers. This allows manufacturers to capture complex sales agreement terms, track performance against planned quantities, integrate order data from ERP systems, and forecast demand more accurately, thereby bringing predictability and visibility to a typically unpredictable business model.

While Salesforce Manufacturing Cloud offers robust solutions for managing manufacturing operations, integrating it with backend systems like SAP and legacy mainframe systems can be challenging. This is where MuleSoft and the Anypoint Platform come into play.

What we'll cover in this article: We’ll explore how MuleSoft accelerates run-rate business integration and enhances demand forecasting and planning for Salesforce Manufacturing Cloud.

Manufacturing integration challenges

Manufacturers often face significant hurdles in integrating disparate systems, which leads to data silos and difficulties with real-time synchronization. These persistent issues prevent a unified view of critical data and complicate overall operations. Ultimately, achieving successful integration hinges on effectively overcoming these complex challenges.

Integrating specialized enterprise systems into unified platforms presents significant challenges for manufacturers. This is especially true for large ERP systems like SAP and legacy mainframes, whose rigid architectures hinder modification and data exchange.

Maneuvering around these rigid architectures and outdated technologies creates an additional layer of complexity that must be addressed carefully during system integration efforts. These specific system types require specialized knowledge to ensure that data can flow correctly without compromising the stability of the enterprise backbone.

To overcome data silos, real-time sync issues, and rigid legacy and ERP integrations (like SAP), a flexible, modern solution is needed. Anypoint Platform solves these challenges by connecting all enterprise components seamlessly.

Anypoint Platform: A game-changer

MuleSoft’s Anypoint Platform offers a comprehensive integration solution that addresses these challenges. MuleSoft provides a unified platform for API-led connectivity, enabling seamless integration with ERP systems like SAP and legacy mainframe systems. Key capabilities include:

- Pre-built connectors for SAP and other ERP systems

- API management and design

- Real-time data synchronization

- Robust security and governance

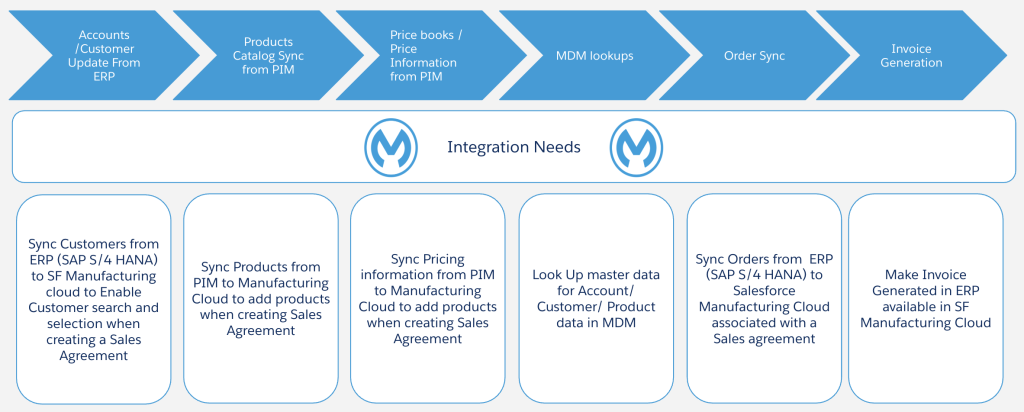

Run-rate business integration use case touch points

Now, let’s explore the typical Integration touch points involved in a typical run-rate business integration use case between Salesforce and legacy systems or ERP.

Now, let’s go through the data synchronization process steps in further detail.

6 core integration requirements

Lets see how MuleSoft addresses six key integration needs related to a run-rate business:

- Customer synchronization: Enables syncing customer data from SAP S/4 HANA to Salesforce Manufacturing Cloud, providing customer search and selection capabilities during sales agreement creation.

- Product catalog integration: Synchronizes products from PIM to Manufacturing Cloud, ensuring sales teams have access to current product information when creating sales agreements.

- Pricing management: Integrates pricing information from PIM to Manufacturing Cloud, allowing dynamic pricing to be applied during sales agreement creation.

- Master data lookups: Provides centralized lookup capabilities for account, customer, and product master data through MDM systems.

- Order processing: Synchronizes orders from SAP S/4 HANA to Salesforce Manufacturing Cloud, maintaining order data consistency across platforms.

- Invoice automation: Generates invoices in ERP systems based on Manufacturing Cloud data, completing the order-to-cash cycle.

While this may look overwhelming, the integration complexity is amplified, when organizations have age-old order management systems in legacy mainframes systems in their application landscape.

Legacy mainframe migration with modern cloud integration

The modernization journey becomes significantly more complex when organizations must simultaneously migrate decades-old order management systems from legacy mainframes to modern SAP environments while implementing Salesforce Manufacturing Cloud. This dual transformation creates a multi-dimensional integration challenge that requires careful orchestration to maintain business continuity.

Seamless legacy migration with MuleSoft

Phased migration strategy: Anypoint Platform enables a gradual, risk-mitigated approach by creating integration layers that can simultaneously connect to both legacy mainframe systems and new SAP environments. This allows organizations to migrate specific business functions incrementally while maintaining operational stability.

Data transformation and translation: Legacy mainframe data often exists in formats like COBOL copybooks, fixed-width files, or proprietary database structures. MuleSoft’s extensive connector library and transformation capabilities can translate these legacy data formats into modern standards, ensuring seamless data flow between mainframe systems, SAP, and Salesforce Manufacturing Cloud.

Dual system operations: During the transition period, MuleSoft facilitates parallel operations by routing specific transactions to appropriate systems based on business rules. For example, existing customer orders might continue processing through mainframes while new product lines route through SAP, with all data synchronized to Salesforce Manufacturing Cloud for unified visibility.

Legacy system preservation: MuleSoft’s mainframe connectors (IBM CICS, IMS, DB2) preserve investments in legacy business logic while gradually exposing mainframe functionality as modern APIs. This approach allows organizations to maintain critical mainframe processes while building new capabilities in SAP.

Real-time data synchronization: The platform ensures data consistency across all three environments: legacy mainframes, SAP, and Salesforce through real-time synchronization, preventing data discrepancies during the migration period.

Risk mitigation: MuleSoft’s monitoring and error handling capabilities provide visibility into integration flows across all systems, enabling quick identification and resolution of issues that could impact business operations during the complex migration process.

This comprehensive integration approach allows organizations to modernize their technology stack without disrupting critical business operations, ultimately achieving a unified, modern enterprise architecture that leverages the best of legacy investments and new cloud capabilities.

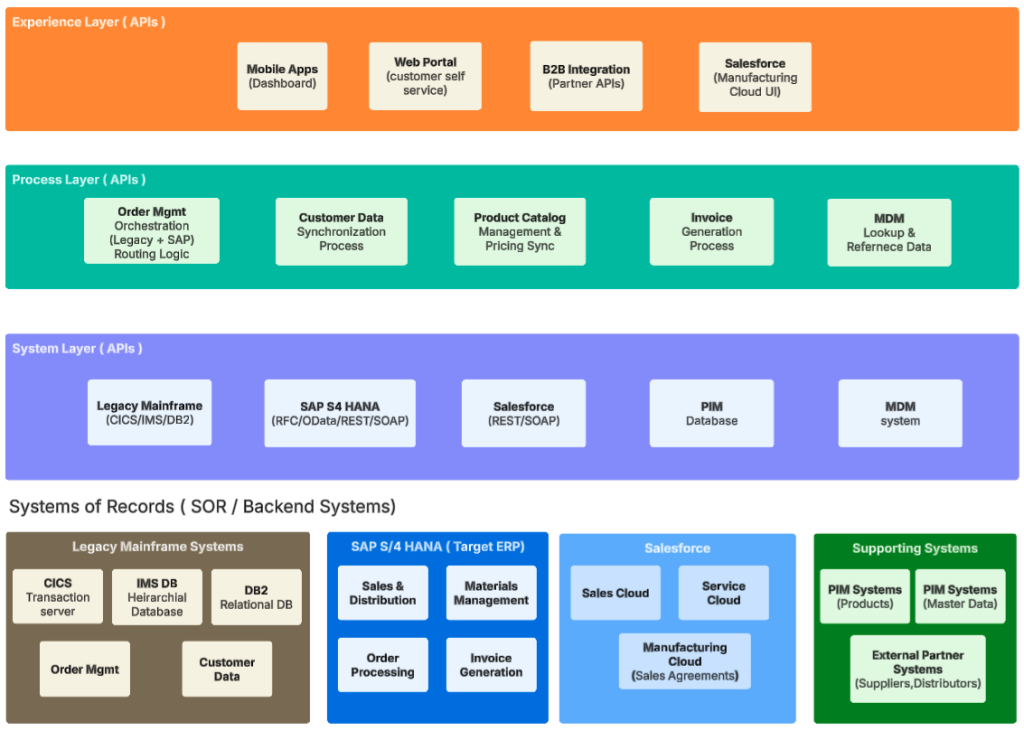

Sample reference architecture

This integration architecture enables seamless data flow between enterprise systems while maintaining data integrity and enabling efficient sales processes across the manufacturing organization.

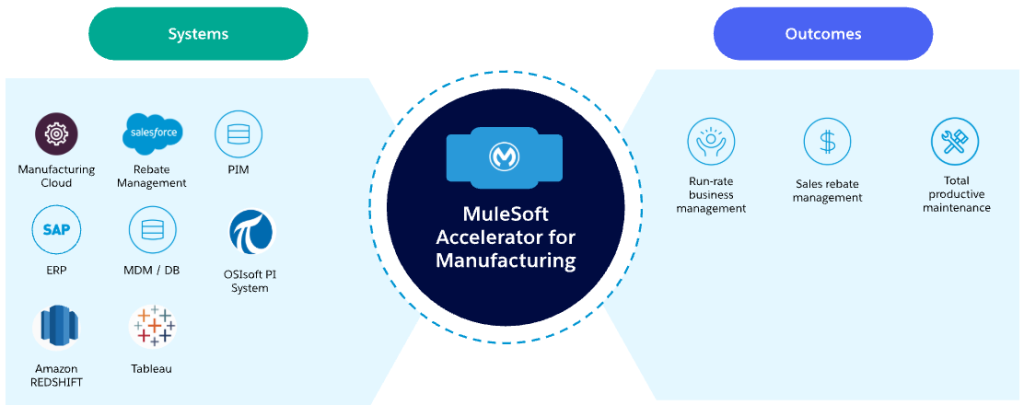

MuleSoft Accelerators in Anypoint Exchange for Salesforce Manufacturing Cloud and SAP

MuleSoft Accelerators provide pre-built integration templates and best practices to streamline the integration process. These accelerators enable seamless data flow between Salesforce and SAP, enhancing visibility and operational efficiency. By leveraging these tools, businesses can quickly implement robust solutions for demand forecasting and run-rate business integration, reducing time-to-market and driving better decision-making.

Powering manufacturing with MuleSoft

MuleSoft and Anypoint Platform integrate Salesforce Manufacturing Cloud with backend systems, accelerating integration and improving demand forecasting. This helps manufacturers stay competitive and modernize systems like SAP without disruption.

As the manufacturing industry continues to evolve, the need for seamless integration and accurate demand forecasting will only grow. MuleSoft is well-positioned to help manufacturers meet these challenges head-on.